The tyre is the only part of the car that touches the road. They must strike a balance between traction, comfort, durability, energy efficiency and overall cost. As a result of these competing needs, tyres are more complex to design and build than you might think.

So let’s go..

THE MANUFACTURING PROCESS

Blend

Up to 30 different kinds of rubber, fillers and other ingredients are used in your tyre’s rubber. The ingredients are mixed in giant blenders to create a black, gummy compound that will be sent on for milling.

Mill

The cooled rubber is cut into strips that will form the basic structure of the tyre itself. At the milling stage, other elements of the tyre are prepared, some of which are then coated in another type of rubber.

Build

It’s now time to make the tyre – from the inside out. The textile elements, steel belts, beads, ply, tread, and other components are placed in a tyre-building machine. The result is a ‘green tyre’ – a tyre that is beginning to look finished.

Cure

The green tyre is then vulcanised with hot moulds in a curing machine, compressing all of the parts of the tyre together and giving the tyre its final shape, including its tread pattern and manufacturer’s sidewall markings.

Inspect

Trained inspectors using special machinery will now carefully check each tyre for the slightest blemish or imperfection before it can be shipped for sale. In addition to that, a selection of tyres are pulled from the line for x-raying to check for potential internal weaknesses or failures. Quality control engineers also randomly select tyres off the line and cut them open to ensure they meet pre-determined standards.

Related Topic You Should Read: 5 ways your car tyres will help you save petrol.

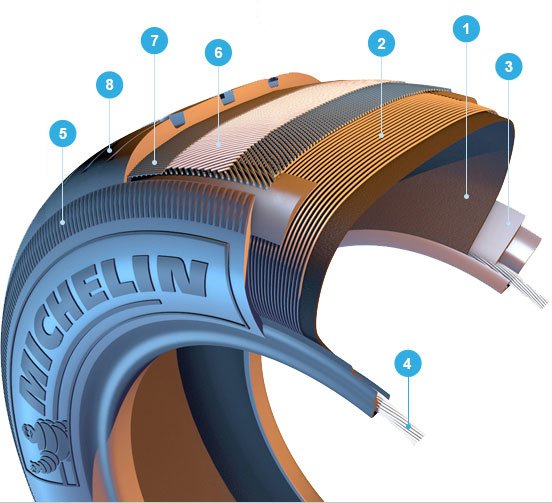

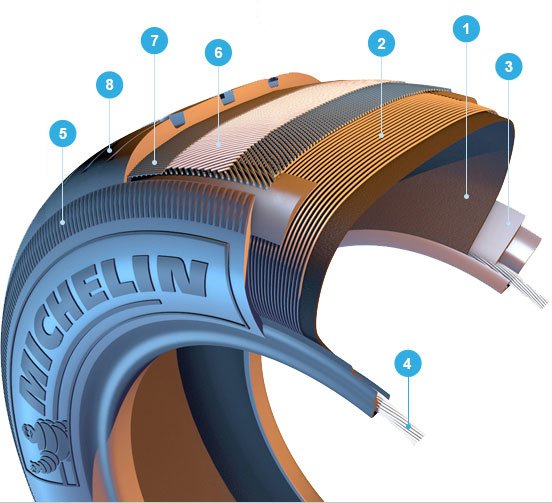

1-Inner liner:

An airtight layer of synthetic rubber (the modern equivalent of an inner tube)

2-Carcass Ply:

The layer above the inner liner, consisting of thin textile fiber cords (or cables) bonded into the rubber. These cables largely determine the strength of the tyre and help it resist pressure. Standard tyres contain about 1,400 cords, each one of which can resist a force of 33lb.

3-Lower bead area:

This is where the rubber tyre grips the metal rim. The power from the engine and braking effort is transmitted from the rim of the tyre to the contact area with the road’s surface.

4-Beads:

They clamp firmly against the tyre’s rim to ensure an airtight fit and keep the tyre properly seated on the rim. Each wire can take a load of up to 3, 968 lbs without risk of breaking. There are eight of them on your car – two per tyre. That’s a massive 31,746 lbs of resistance strength. An average car weighs about 3,307 lbs.

5-Sidewall:

It protects the side of the tyre from impact with curbs and the road. Important details about the tyre are written on the sidewall, such as tyre size, speed rating, etc.

6- Crown plies (or belts):

It largely determines the strength of the tyre. It’s made up of very fine, resistant steel cords bonded into the rubber. This means the tyre can resist the strains of turning, and doesn’t expand due to the rotation of the tyre. It’s also flexible enough to absorb deformations caused by bumps, potholes and other obstacles in the road.

7-Cap ply (or “zero degree” belt):

This important safety layer reduces friction heating and helps maintain the shape of the tyre when driving fast. To prevent centrifugal stretching of the tyre, reinforced nylon based cords are embedded in a layer of rubber and placed around the circumference of the tyre.

8- Tread:

It provides traction and turning grip for the tyre and is designed to resist wear, abrasion and heat.

Don’t forget to like, rate, share and also download our android app.

News1 week ago

News1 week ago

News1 week ago

News1 week ago

News1 week ago

News1 week ago

News1 week ago

News1 week ago

News4 days ago

News4 days ago

Latest Cars1 week ago

Latest Cars1 week ago

News1 week ago

News1 week ago

News1 week ago

News1 week ago